Protecting Your Techs & Trucks

Two important challenges our customers face in the lawn care industry are acquiring and retaining technicians and securing the work trucks needed to safely and efficiently get from job to job. Labor shortages and supply chain issues have made these challenges even more difficult. Plus, the costs of wages, vehicles, raw materials, commercial auto insurance and fuel all continue to rise.

There are tools to reduce the risks associated with your technicians’ driving behavior and motor vehicle records. Better driving reduces the wear and tear on your vehicles, which saves you money by reducing maintenance costs and downtime in the shop. With fuel accounting for 39% of total operational costs, reevaluating your fuel optimization strategy can help you save money at the pump.

Get the Most Out of Your Most Valuable Assets

If your technician is in an accident, you’re out of a truck for that day; possibly for several days or weeks while it’s being repaired or replaced. At best, your tech is sitting on the side of the road waiting for a tow truck, if not injured. Regardless of the severity of the accident, his day is going to be very unproductive. Depending on the time of day, there may be several appointments that still need to be completed, forcing your office staff to adjust the schedules of other technicians.

On average, technicians are behind the wheel of your expensive, beautifully wrapped, fully outfitted truck for about two hours a day. First, you didn’t hire them for their responsible and defensive driving skills. When your technicians describe their role, they rarely mention being a “driver.” Second, you want them to get to every job as quickly and efficiently as possible. There are competing priorities at play. Racing from light to light, aggressive cornering and speeding all have a detrimental effect on the wear and tear of the vehicle’s engine, transmission and tires. Still, more importantly, your accident risk profile increases dramatically.

Incentives Drive Behavior

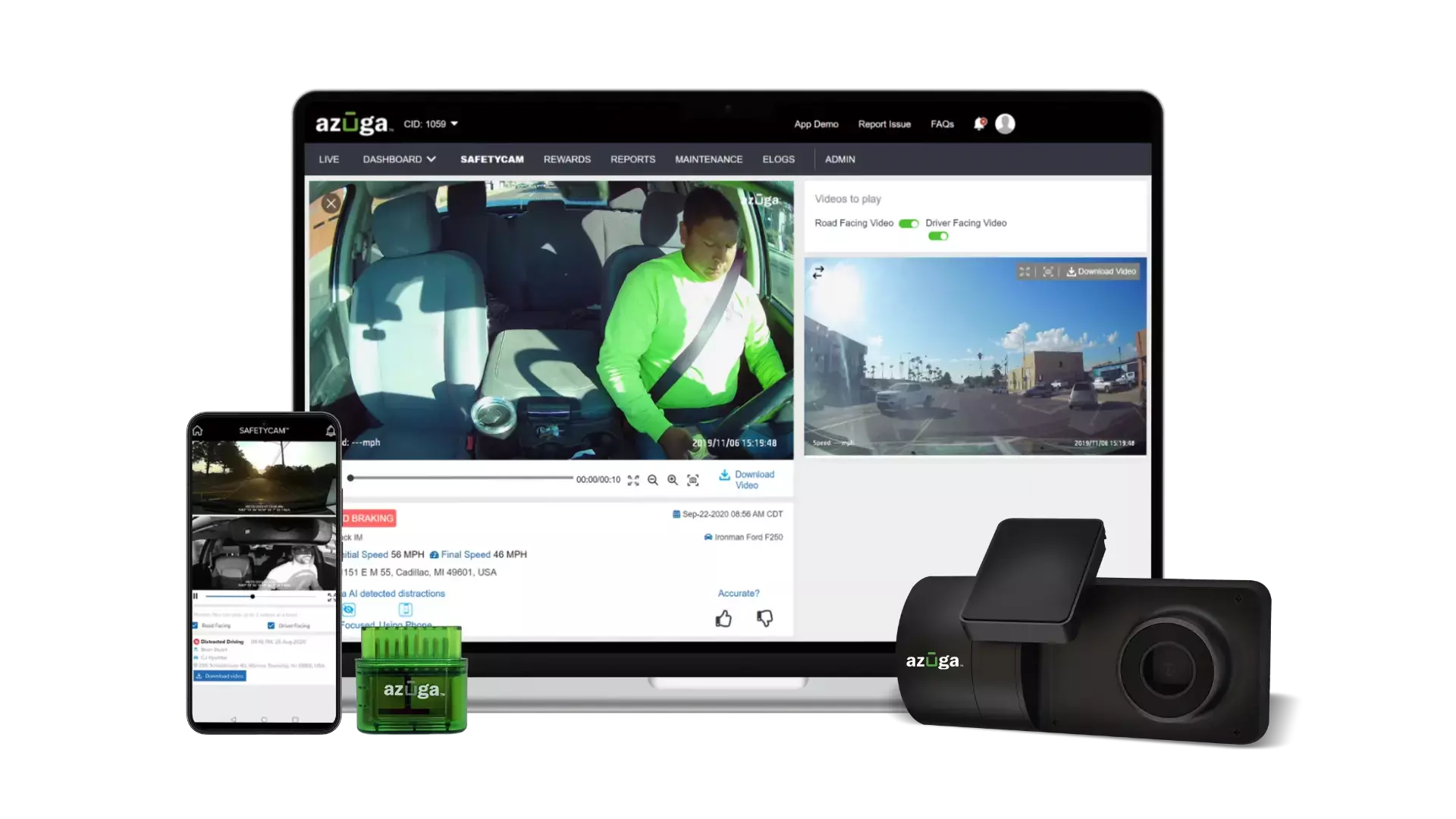

The costs associated with operating your trucks are not directly relevant to your techs, but they can be with the right incentives. When techs can see how their driving stacks up against the entire team, it creates a culture of awareness that markedly reduces idling, speeding and aggressive driving. This results in lower fuel and maintenance costs, as well as less risky driving behavior. When technicians compete for the best driving score, everyone wins. Make sure to incentivize with a financial reward.

Watch Your Back

For a few hours each day, your company truck is on the road screaming, “I one-hundred-percent have commercial auto insurance!” If you have your name on your truck, you are a target for many law firms. So, how are you minimizing your liability from frivolous nuclear lawsuits?

On average, 70% of all accidents involving commercial vehicles are not the fault of the driver. However, in the age of nuclear lawsuits, if there is no video evidence, you are often guilty until proven innocent, and your insurance company may just settle the case to limit the damage. Smart safety cameras protect your business by continuously recording and sending videos to the cloud. The more advanced cameras will monitor for poor driving behavior and assist in correcting common distractions. Regardless, having a record of what actually happened enables you to protect your business from frivolous lawsuits while also protecting each technician’s driving record.

Minimize Unscheduled Downtime

Scheduled maintenance is an often overlooked operational challenge. Vehicles are pretty smart; they monitor their own health and provide engine fault codes, alerting you to problems with the engine, brakes, tires, etc., in real-time. However, any warning a technician sees in the vehicle is minimal and often does not get communicated quickly to the right people. The same code reader mechanics use to identify the fault code and corresponding severity can be delivered using modern vehicle tracking systems. DO NOT rely on your techs to report these issues.

Automated reports provide detailed information on maintenance tasks and keep track of vehicles that require assistance soon. You should set up alerts and reminders based on odometer readings and fault codes for services due, such as oil changes, brake jobs, tire rotations, and other preventative services or vehicle inspections.

Automotive Fleet Magazine reported that proper maintenance can improve fuel economy by as much as 40%, and the U.S. Department of Energy states that proper tire pressure can improve your gas mileage by 0.6% on average, up to 3% in some cases. Additionally, a labor shortage within the automotive repair industry is causing delays in routine repairs, which can range from hours to days. Shifting from reactive to proactive maintenance will reduce your operational costs and increase the efficiency of your technicians.

Be safe!

Written in partnership with Matt Curtis, Vice President of Partnerships at Azuga, a Bridgestone Company.